Contents

1 Introduction

Staff are our greatest asset, and our health and safety is important to us all.

There is need therefore, for staff to understand how to undertake safe manual handling practices, whilst the trust ensures legal responsibility to reduce the risk of injury. Poor manual handling techniques can result in musculoskeletal disorders, back pain and upper limb disorders. It is therefore essential that all staff receive appropriate manual handling training to enable them to carry out their duties safely and effectively.

The Manual Handling Operations Regulations (1992) (amended 2002) made under the Health and Safety at Work Act came into force on 1st January 1993 (European Directive 90/269/EEC). Under the regulations, employers must seek to avoid manual handling where possible. Where this is not possible they are required to adopt an ergonomic approach to removing or reducing the risk of manual handling injuries through safe systems of work and a safe working environment.

The ergonomic approach looks at manual handling as a whole, taking into account a wide range of relevant factors including the nature of the task, the load, the working environment and individual capability.

2 Purpose

The purpose of this policy is to set out the trust’s arrangements associated with manual handling for:

- identifying and managing the risks associated with manual handling. This includes carrying out risk assessments, providing appropriate supervision and developing safe working procedures

- ensuring the delivery of effective manual handling training to all staff, including the safe use of mechanical equipment in order to reduce the risks associated with manual handling

- promoting balanced decision-making between patients’ needs and comfort and staff safety needs and competence. Recognising that safe methods of manual handling have considerable benefits for patients, including increased independence and personal safety

3 Scope

This policy applies to all staff who are employed by the trust, agency staff, students and volunteers who carry out manual handling activities, regardless of their location and covers the manual handling and lifting all objects and patients.

4 Responsibilities, accountabilities and duties

4.1 Chief executive

The chief executive as accountable officer of the trust has overall accountability for ensuring the trust meets statutory requirements. The responsibility for the management of manual handling is devolved to directors, managers, heads of department and to all trust staff.

4.2 The board of directors, deputy care group directors, corporate heads of service and managers

The board of directors, deputy heads of service, corporate heads of service and managers are responsible for ensuring that the trust consistently follows the principles of good governance applicable to NHS organisations. This includes the development of systems and processes to reduce the risk associated with manual handling. Their duties include and are not limited to:

- be responsible for ensuring this policy is publicised and implemented

- seek advice from the Manual Handling team where new services or service models are developed, or where new systems and tasks are introduced, in order that workplace planning and design with regard to the elimination of manual handling hazards can be considered at an early stage

- make available adequate resources to meet the needs outlined within this policy

- in line with the medical devices management policy, maintain an up to date medical devices inventory, listing relevant moving and handling equipment, accessories and other aids, servicing requirements and training needs, and for making available up to date maintenance records

- implement a plan for all manual handling equipment and accessories to be thoroughly examined, serviced and maintained in accordance with The Lifting Operations and Lifting Equipment Regulations (LOLER), 1998 and The Provision and Use of Work Equipment Regulations (PUWER), 1998

- ensure that staff under their management complete induction training and trust agreed periodic training in safer manual handling operations

- identify staff to act as manual handling key trainers within their area of control

- work in consultation with the manual handling key trainer for their areas to ensure that hazardous manual handling tasks are identified and risk assessed to enable the most appropriate risk reduction measures to be developed and used

- make a written record of the risk assessments for their areas of control and communicate the findings to all staff involved

- introduce appropriate risk reduction measures to avoid or reduce risk. This may include the use of mechanical aids or a redesign of the manual handling task. Make available suitable and sufficient mechanical aids that are easily accessible for staff use

- plan for adequate staffing where a risk assessment indicates that additional staffing is required

- avoid the need for staff to undertake any manual handling operations which involve a risk of injury, so far as is reasonably practicable

- monitor and review manual handling risk assessments when there is a reason to suppose that they are no longer valid due to accidents, changes in working conditions, personnel involved or a significant change in the manual handling operations affecting the nature of the task or the load

- clearly identify manual handling requirements of each job role when recruiting staff so that appropriate Occupational Health assessment can be undertaken as part of pre-employment health screening

- make reasonable adjustments for any known health problems or pregnancy which might have a bearing on an existing employee’s ability to carry out manual handling operations in safety

- refer to occupational health if there is reason to suspect that an individual’s health might increase the risk of injury from manual handling operations

- maintain records of incidents and ill-health issues related to manual handling operations and investigate the circumstances surrounding the incident

- refer to the trusts fast track physiotherapy service as appropriate to maximise staff recovery

4.3 Health and safety lead

Duties of the health and safety lead include but are not limited to:

- monitor the incidence and severity of all manual handling incidents throughout the trust and report on these to the health, safety and security forum

- liaise with the Manual Handling team in the investigation of manual handling incidents, analysis of causation and development of remedial action where appropriate

4.4 Health, safety and security forum

The purpose of the health, safety and security forum is to monitor and promote effective health and safety measures at work (HASAWA, 1974, s 2 (7), through communication and collaboration between the trust and its employees on health and safety matters. A member of the Manual Handling team attends health, safety and security forum.

4.5 Manual Handling team

Duties of the Manual Handling team include and are not limited to:

- develop, implement and monitor safe systems of manual handling throughout the trust

- develop a trust wide action plan based on risk assessments and review this on an annual basis

- provide manual handling training for new starters as part of the trust corporate induction

- train the manual handling key trainers in both object and patient handling as appropriate and update them on an annual basis

- provide ongoing support and supervision to the manual handling key trainers

- be available as a source of expert, specialist advice to managers, staff and manual handling key trainers in the workplace

- maintain an up to date list of manual handling key trainers and accurate training records for monitoring or inspection purposes

- assist managers to undertake manual handling risk assessments and training needs analysis where new services or service models are developed, or where new systems and tasks are introduced

- monitor and advise on the sufficiency of the model of manual handling training

- following referral by a manager, conduct an assessment and provide advice in relation to manual handling in the workplace in order to assist a staff member’s return to work

- investigate manual handling incidents as requested by managers

- be involved in the assessment, trial and training associated with the implementation of new equipment to reduce manual handling risks

- provide advice to managers with regard to pregnancy risk assessments in line with trust policy

- maintain a network of links with specialist advisors such as tissue viability, infection control and health and safety lead

- maintain records of all assessments and advice given

4.6 Manual handling key trainers

Duties of manual handling key trainers include and are not limited to:

- act as champions for safer manual handling operations, promoting trust policy and best practice

- work closely with managers to identify and risk assess manual handling tasks and to enable the most appropriate risk reduction measures to be developed and used

- train staff in up to date manual handling techniques, systems and legislation on a maximum ratio of 1 trainer to 6 staff

- provide the Manual Handling team with records of all training delivered

- attend an annual update provided by the Manual Handling team

- liaise with the Manual Handling team on an ongoing basis with regards to manual handling issues in their teams or service areas

- maintain risk assessments and personal handling profiles

4.7 All staff

Duties of all trust staff include:

- taking reasonable care of their health and that of others whose safety may be affected by their activities when involved in manual handling operations

- co-operating with their manager in the making of risk assessments of hazardous manual handling tasks

- use the safe systems of work and safety equipment provided, promptly reporting any defects in handling equipment to their manager. Such equipment must be taken out of use and labelled as not to be used

- participating in statutory manual handling training and update training, annually for clinical staff and three yearly for non-clinical staff

- reporting pregnancy or any medical conditions which may affect their ability to handle loads safely to their manager

- reporting any change in working conditions, personnel involved in manual handling risks or a significant change in the nature of the task or the load, which may necessitate a review of the risk assessment

- maintaining records of risk assessments for dissemination to relevant staff

- wearing suitable work clothing and footwear for manual handling, see uniform and dress code policy

5 Procedure or implementation

The trust is committed to the implementation of a safer manual handling policy based on the following components:

5.1 Arrangements for access to appropriate specialist advice

Advice is provided by the trust’s Manual Handling team (staff access only) (opens in new window) who can be contacted by telephone or email:

The team delivers the trust’s manual handling training programme and when required, will seek the provision of additional external advice or equipment, for example, a piece of specialist equipment.

5.2 Techniques to be used in the moving and handling of patients and objects, including the use of appropriate equipment

5.2.1 Object handling

Object handling is taught according to the manual handling operations regulations approved code of practice which promote conditioning exercises, off-set base and a low centre of gravity.

Guidance continues to be sought from the HSE, The national back exchange and the Doncaster healthcare community manual handling passport.

Agile workers or hybrid workers can access extra support or guidance by clicking on this toolbox (staff access only) (opens in new window).

5.2.2 Load handling

A minimal lifting, individualised approach needs to be applied to load handling situations based on a risk assessment, which takes account of factors such as size, shape, weight and design of the load. Mechanical aids should be utilised whenever possible.

Whenever possible the risk of injury from load handling should be reduced by implementing measures at a strategic level. Good planning and design at the workplace will often eliminate hazards at an early stage.

Safe systems of transportation will be readily available for the movement of goods, supplies and equipment throughout.

5.2.3 Patient handling

The trust recognises that there will always be the need to manually handle patients. To avoid hazardous handling any other consideration must take into account duty of care and balanced decision making. The aim of the policy is to avoid manual lifting of adult patients in all but exceptional or life threatening situations Staff should not be expected to put their safety at risk by lifting manually. However, where there is a need to lift whole body weight, the trust will utilise hoists or similar equipment.

Research shows that lifting techniques formerly developed and practiced can become detrimental and should not be utilised. The following represent such lifts, which should no longer be employed:

- drag lift (banned since 1981)

- orthodox lift

- Australian lift

- lifting with patients arms around neck

- lifting with patients from floor without mechanical aid

- lifting with patients from the base of the bath without an aid

- lifting with patients by the upper arm

- lifting with sheet parallel to the bed

Staff who are unsure or concerned about any techniques currently being practiced should seek advice from a manual handling key trainer or the Manual Handling team.

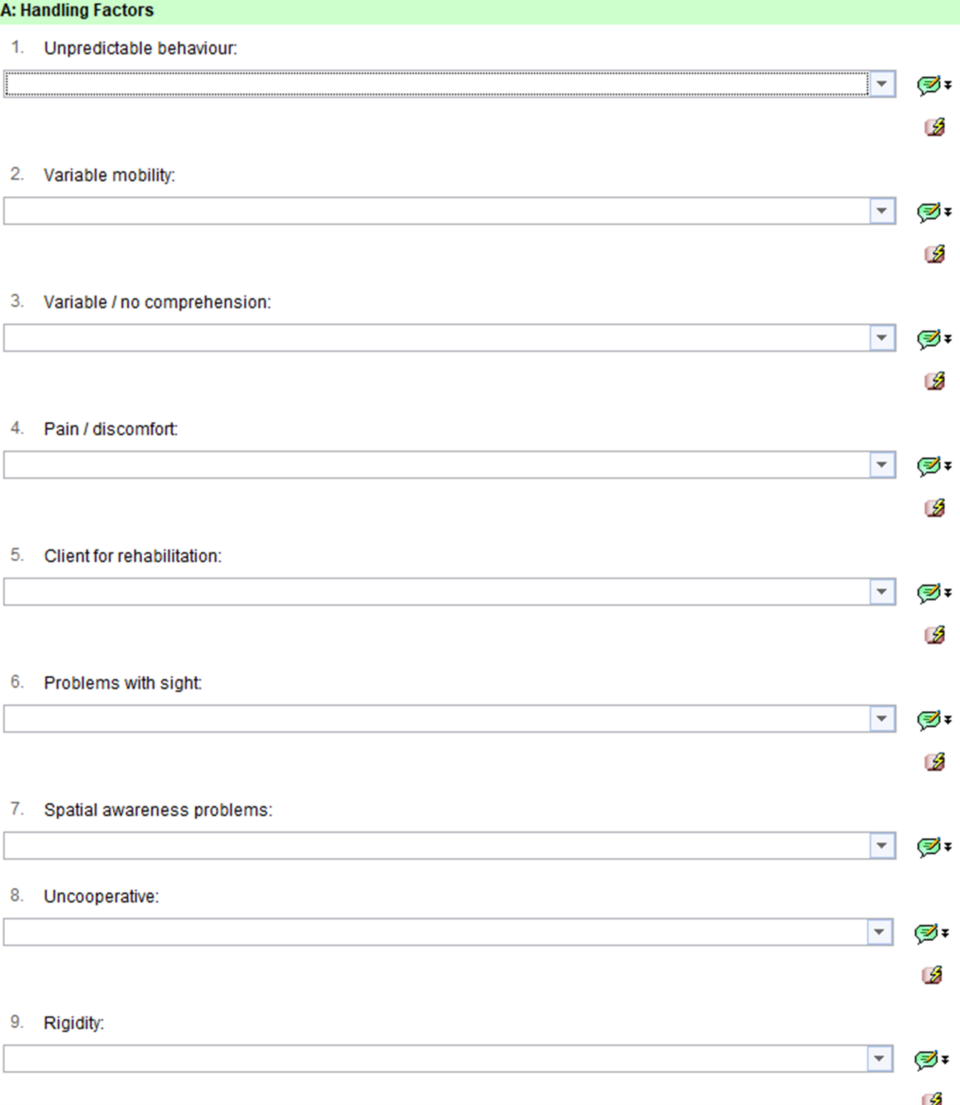

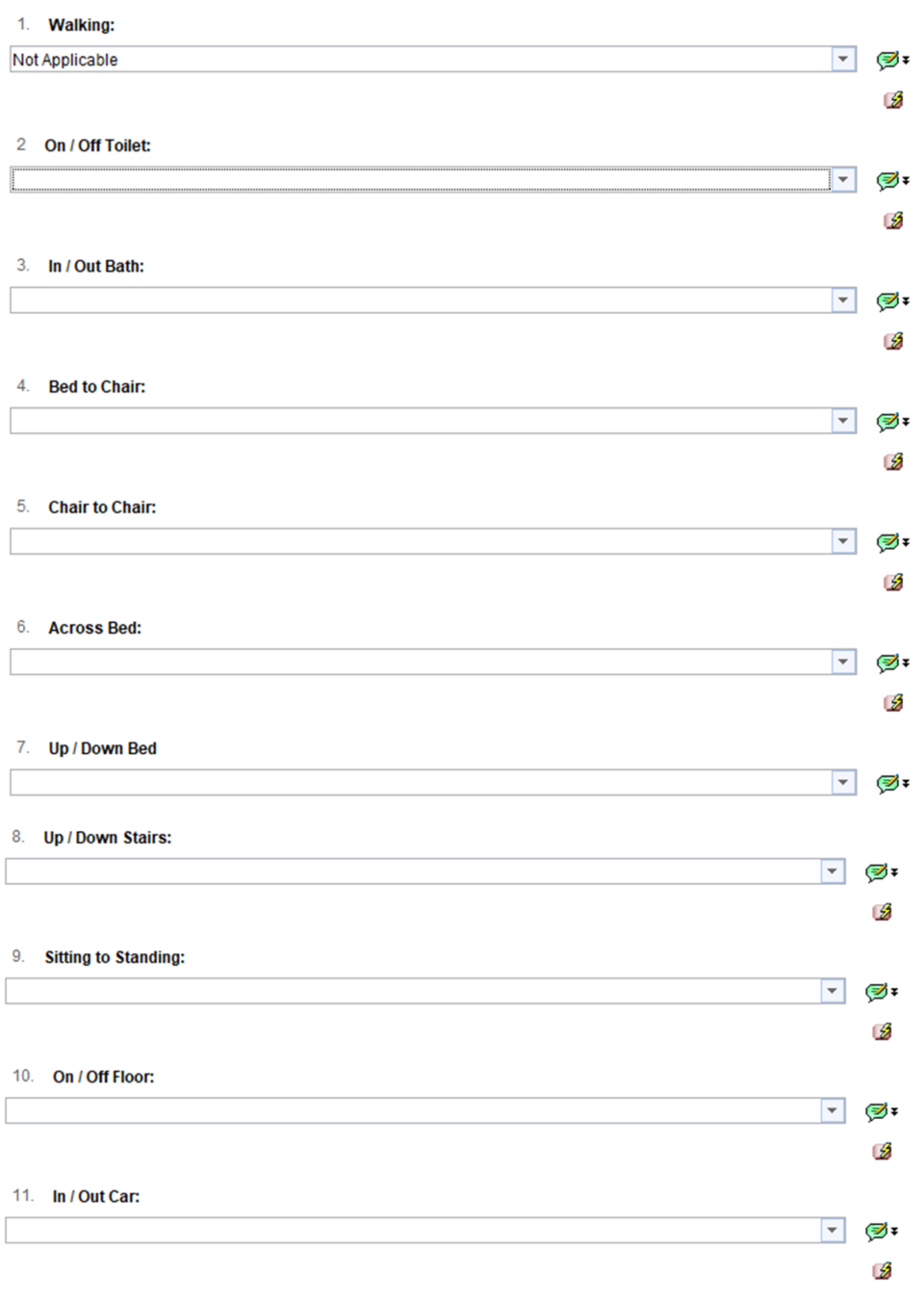

Each patient will be risk assessed considering their individual circumstances and will be encouraged to be actively involved in the assessment and decision-making process.

The rehabilitation and developmental needs of patients will also be considered in addition to staff, carer and patient safety.

Manual handling techniques may be used based on an individual risk assessment provided that they follow safer handling principles. Advice should be sought from a manual handling key trainer or the Manual Handling team in complex cases.

Note, for larger patients staff should refer to the bariatric policy (Care of the bariatric patient).

Risk assessments and manual handling action plans are filed in the patient record, SystmOne and shared with the staff team. These should be reviewed at appropriate intervals or when circumstances change.

5.2.3.1 Manual handling within the patient’s own home

Householders cannot be required by health and safety law to adapt their home or use equipment provided to reduce risks to visiting care staff. However, with their co-operation, much can be done to eliminate or reduce the risks from manual handling, particularly by modifying the home environment to improve working postures of staff and carers.

When the patient is being discharged from hospital, forward planning is essential to ensure that arrangements have been made for environmental adaptations, equipment provision and staff training. Risk assessments should also be undertaken for the issue and delivery of equipment ensuring that safe systems of transportation are employed.

While the patient or their carers have no duty under health and safety law to cooperate with the employer, organisations have a duty to staff when working in patient’s homes.

Before patients are discharged from hospital to their own home, it is important that the appropriate manual handling equipment is in place. A written risk assessment and individual movement plan must also be available for any community staff involved.

Where a risk assessment has been completed by a partner organisation or other health or social care practitioner the content of the risk assessment and the recommendations will be recorded within the patient’s care record.

5.2.4 Rehabilitation handling of patients

Care handling is where manual handling needs to be avoided and mechanical equipment, such as hoists, are to be used for patients who are non-weight bearing or unable to transfer safely.

Rehabilitation handling is where handling is performed as an integral part of a planned therapeutic intervention and risk must be reduced in other ways. Specialist equipment, including the use of standing and transferring aids and additional staff may be required so that patients can achieve the optimum level of independence and mobility.

Certain groups of staff (particularly physiotherapists and occupational therapists) include physical handling as part of the therapeutic interventions they provide. The techniques should be based on safer handling principles and utilise equipment where relevant, as determined by the manual handling risk assessment and movement plan.

Managers responsible for such staff should ensure that patient rehabilitation programmes minimise the risk to staff or carers. Adequate staffing levels and sufficient rehabilitation equipment should be provided, along with specific risk assessments and training.

5.2.5 Workplace and environmental design

Consideration should be given to the suitability of the ergonomics for the task, such as the arrangement of doors and positioning of equipment. If necessary and possible, adjustments should be made to the environment to make the task safer.

5.2.6 Provision and use of equipment

The risk assessment may identify the need for the provision of manual handling equipment as a risk reduction measure. The manager obtaining the equipment (an authorised requisitioner) will consult with staff and the Manual Handling team on the appropriateness of the intended equipment. This may identify the opportunity to have equipment demonstrated and trialled prior to purchase.

5.3 How the trust risk assesses the moving and handling of patients and objects (further information is provided in appendices A and B)

5.3.1 Manual handling risk assessment

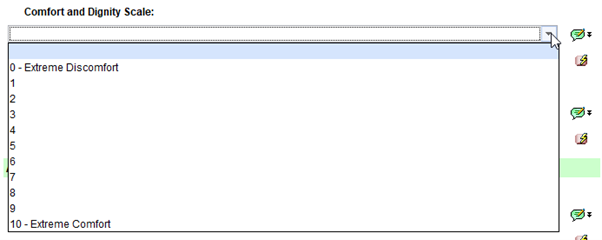

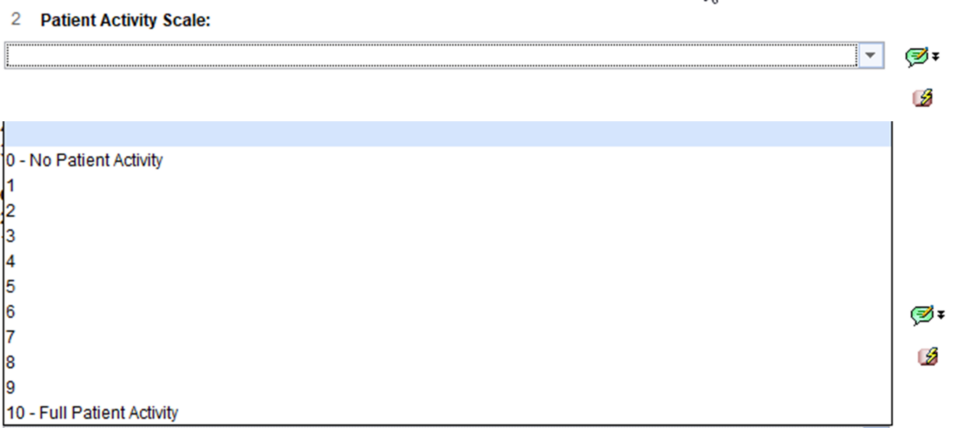

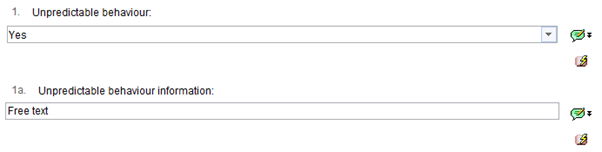

There are two risk assessments, one for object risks and patient specific risks (appendix A) and one for patients (appendix B). The patient specific risk assessment can be completed on SystmOne

Staff are trained in using these through the moving and handling training programme.

Where a referral is made to the manual handling service for advice, a risk assessment must be provided by the referrer.

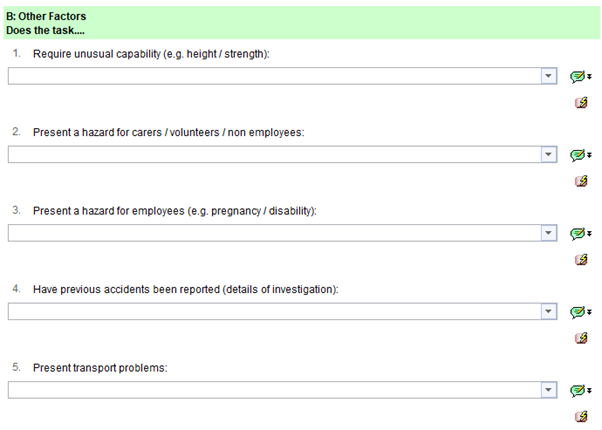

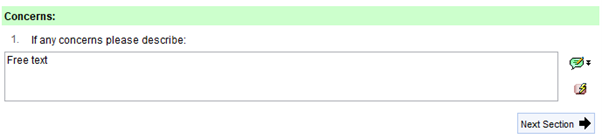

The Manual Handling Operations Regulations, 1992 (amended 2002) specify that Task, Individual Capability, Environment, and Load (TILE) are all taken account of as part of a comprehensive risk assessment. The Manual Handling Risk Assessment forms shown in appendices A and 2 for Load or object handling and patient handling facilitate this. Risk assessments should be either generic or specific to the situation.

It is strongly recommended that more than one person completes the risk assessment so that a balanced decision can be reached.

There is evidence to suggest that patient handling risk assessments completed jointly by a qualified and unqualified member of staff lead to higher compliance with patients care plans due to the nursing assistant’s involvement (Hignett et al, 2003).

Manual handling risk assessments will be recorded on the trust’s approved risk assessment documentation, which is in appendices A and 2.

5.4 How action plans are developed as a result of risk assessments

- A trust wide action plan based on risk assessments is developed and reviewed as specified. This is also used to inform a review of manual handling training.

- For objects, action plans are written on the risk assessment forms.

- When reviewing the patient moving and handling assessment form staff should also consider the patient care plans and any other risk assessments to inform any changes to the moving and handling assessment form.

- For complex patients a personal handling profile is completed and added to the notes.

- These records are stored electronically.

- Some risk assessments will lead to equipment adaptations or adjustments to reduce manual handling risks to the carer and or the patient. The proposed changes are likely to be more acceptable to the patient and their family if they have been fully involved in the assessment process and understand the purpose for which it has been carried out.

- However, even where there has been involvement in the assessment, a minority of people are reluctant to address the risks identified. This places the service provider in a difficult situation as they have a duty with regard to staff health and safety and also the quality of care to the patient. It is not acceptable under health and safety legislation to allow unsafe work practices to continue.

- In instances where there is disagreement it should be borne in mind that a balanced approach is needed to ensure that:

- staff are not required to perform tasks that put them and patients at risk unreasonably

- the patient’s personal wishes on mobility assistance are respected wherever possible

- Where there is a difference of opinion, therefore, an urgent meeting with the patient, their family and the relevant manager should be held to discuss the risk assessment and care plan in order to agree a way forward.

5.5 How action plans are followed up

Action plans are followed up by a 30 day review by the Manual Handling team.

6 Training implications

The training needs analysis (TNA) for this policy can be found in the training needs analysis document which is part of the trust’s mandatory and statutory training policy located under the policy section of the trust website.

7 Monitoring arrangements

7.1 Duties

- How: Report.

- Who by: Manual Handling team.

- Reported to: Health, safety and security forum.

- Frequency: Annual.

7.2 Techniques to be used in the moving and handling of patients and objects including the use of appropriate equipment

- How: Report: Key trainer and individual referral for cases to the manual handling team and through incident reports and claims.

- Who by: Manual Handling team.

- Reported to: Health, safety and security forum.

- Frequency: Annual.

7.3 Arrangements for access to appropriate specialist advice

- How: Report, email and referral system.

- Who by: Manual Handling team.

- Reported to: Health, safety and security forum.

- Frequency: Annual.

7.4 How the organisation risk assesses the moving and handling of patients and objects

- How: Training and manual handling key trainer supervision.

- Who by: Manual Handling team.

- Reported to: Health, safety and security forum.

- Frequency: Annual.

7.5 How action plans are developed as a result of risk assessments

- How: Report.

- Who by: Manual Handling team.

- Reported to: Health, safety and security forum.

- Frequency: Annual.

7.6 How action plans are followed up

- How: Report, key trainer and individual referral or for cases to the Manual Handling team and through incident reports and claims.

- Who by: Manual Handling team.

- Reported to: Health, safety and security forum.

- Frequency: 30 day follow up.

8 Equality impact assessment screening

The completed equality impact assessment for this policy has been published on this policy’s webpage on the trust website. Link to equality impact assessment: Safer manual handling equality impact assessment.

8.1 Privacy, dignity and respect

The NHS constitution states that all patients should feel that their privacy and dignity are respected while they are in hospital. High Quality Care for All (2008), Lord Darzi’s review of the NHS, identifies the need to organise care around the individual, ‘not just clinically but in terms of dignity and respect’.

As a consequence the trust is required to articulate its intent to deliver care with privacy and dignity that treats all service users with respect. Therefore, all procedural documents will be considered, if relevant, to reflect the requirement to treat everyone with privacy, dignity and respect, (when appropriate this should also include how same sex accommodation is provided).

8.1.1 How this will be met

There are no additional requirements in relation to privacy, dignity and respect

8.2 Mental Capacity Act 2005

Central to any aspect of care delivered to adults and young people aged 16 years or over will be the consideration of the individuals capacity to participate in the decision making process. Consequently, no intervention should be carried out without either the individual’s informed consent, or the powers included in a legal framework, or by order of the court.

Therefore, the trust is required to make sure that all staff working with individuals who use our service are familiar with the provisions within the Mental Capacity Act (2005). For this reason all procedural documents will be considered, if relevant to reflect the provisions of the Mental Capacity Act (2005) to ensure that the rights of individual are protected and they are supported to make their own decisions where possible and that any decisions made on their behalf when they lack capacity are made in their best interests and least restrictive of their rights and freedoms.

8.2.1 How this will be met

All individuals involved in the implementation of this policy should do so in accordance with the guiding principles of the Mental Capacity Act (2005). (section 1) All assessments are carried out in collaboration with the patient. Should the patient not be able to express their views a best interest meeting is convened to look at the individualised patient’s manual handling needs.

9 Links to any associated documents

- Risk management framework

- Health and safety policy statement

- Health and safety policy

- Display screen equipment (DSE)

- Slips, trips and falls for staff and visitors, prevention and management policy

- Patient falls manual (prevention and management)

- Mandatory and statutory training policy

- Incident management policy

- Medical devices management policy

- Family leave policy

- Hoist and sling for safer patient use policy

- Bariatric policy

10 References

The health and safety executive (HSE) website provides further information and resources for managing the risks associated with manual handling HSE website (opens in new window).

- Manual Handling Operation Regulations 1992, updated 2002.

- Management of Health and Safety at Work Regulations, 1992.

- The Human Rights Act 1998.

- Provision and Use of Work Equipment Regulations, 1998 (PUWER).

- Lifting Operations and Lifting Equipment Regulations, 1998 (LOLER).

- Back Care (2011) The Guide to handling people (6th edition).

- Health and Safety at Work Act 1974.

- Hignett et al (2003) Evidence Based Patient Handling.

11 Appendices

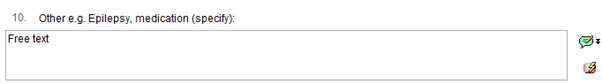

11.1 Appendix A Patient moving and handling questionnaire user guide

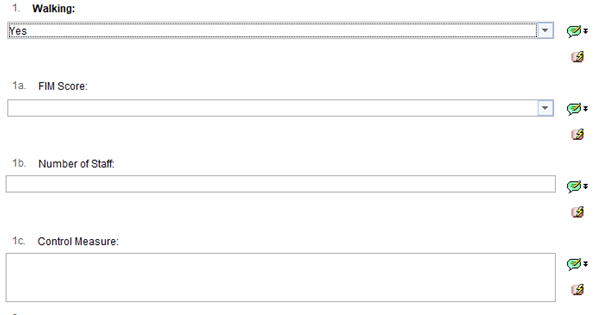

11.1.1 Method of manual handling

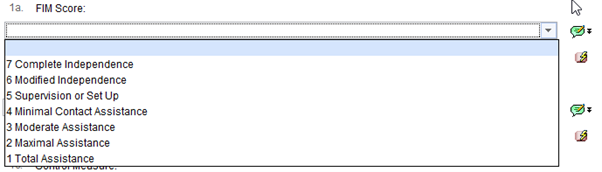

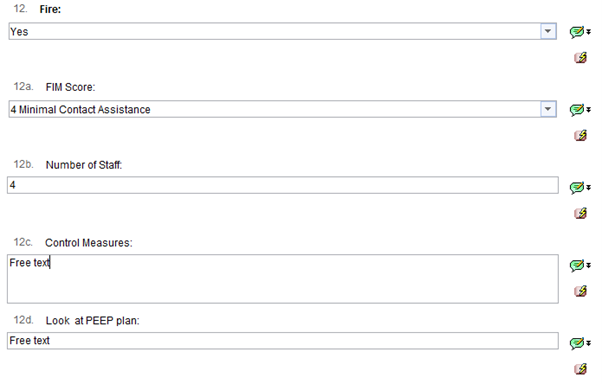

FIM Score (Reference, The Guide to the Handling of People 6th Edition)

Independent, another person is not required for the activity (no helper)

- 7, complete independence

- 6, modified independence

Dependent, another person is required for verbal, gesture, physical prompt setup of environment. Or the task is not performed (requires help)

- 5, supervision or set up

- 4, minimal contact assistance

- 3, moderate assistance

Complete dependence, maximal or total assistance is required. Two people or more required or the task is not performed (requires 2 people to help)

- 2, maximal assistance

- 1, total assistance

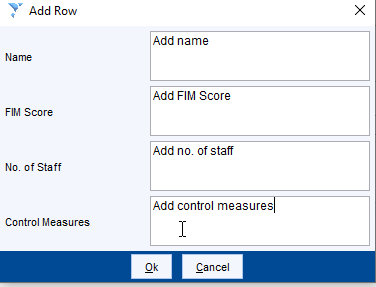

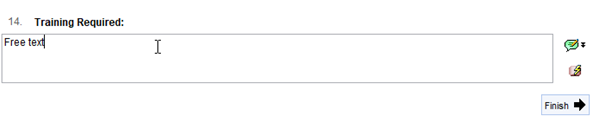

11.1.2 Using a questionnaire tips

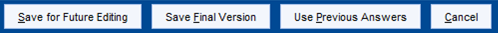

Top left of the screen you will see the below buttons:

- Save for future editing, if you need to leave the questionnaire and come back to it, for example, have it checked, you can save the questionnaire for future editing. To complete the questionnaire you must go back and save as final version.

- Save final version, a questionnaire must be completed as final version once finished.

- Use previous answers, this will allow you to pull through all previous answers used, the questionnaire should still be checked to make sure all the same answers are still relevant.

- Cancel, cancel out of the questionnaire, this will not save anything you have entered.

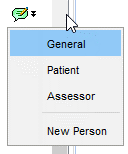

- Lightning bolt, allows you use the previous answer for that specific question.

- Green tick, page has been fully completed.

- Red cross, page has not been started.

- Green cross, page has been started but not fully completed.

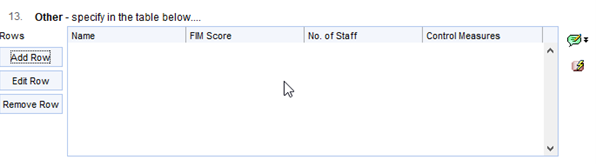

11.2 Appendix B Manual handling risk assessment form

11.3 Appendix C Patient moving and handling assessment form

11.4 Appendix D Personal handling profile

Document control

- Version: 9.1.

- Unique reference number: 223.

- Approved by: Corporate policy approval group.

- Date approved: 11 January 2024.

- Name of originator or author: Manual handling trainer.

- Name of responsible individual: Health, safety and security forum.

- Date issued: 12 January 2024.

- Review date: August 2025.

- Target audience: All staff.

Page last reviewed: April 11, 2024

Next review due: April 11, 2025